The Advantages of Hot Rolled Steel Plates

Hot rolled steel plates are a crucial component in various industries, offering a wide range of advantages that make them indispensable for a multitude of applications. The hot rolling process involves heating steel slabs or billets to high temperatures and then passing them through a series of rollers to achieve the desired thickness and shape. This process imparts specific properties to the steel plates, which contribute to their unique advantages. In this comprehensive guide, we will explore the numerous benefits of hot rolled steel plates and their applications across different sectors.

Understanding Hot Rolled Steel Plates

Hot rolled steel plates are produced through the hot rolling process, which involves heating steel to temperatures above its recrystallization point and then passing it through rollers. This process enables the steel to be shaped and formed into plates of various thicknesses and dimensions. The resulting steel plates possess distinct characteristics that make them highly desirable for a multitude of applications.

Key Advantages of Hot Rolled Steel Plates

1. Cost-Efficiency:

Hot rolled steel plates are typically more cost-effective than cold rolled plates. The hot rolling process consumes less energy, making it a more economical choice for producing large quantities of steel plates. This cost-efficiency is especially valuable in construction and manufacturing applications where large quantities of steel are required.

2. High Tensile Strength:

Hot rolled steel plates exhibit excellent tensile strength, making them ideal for applications that require structural integrity and the ability to withstand heavy loads. This advantage is particularly important in the construction of buildings, bridges, and other infrastructure projects.

3. Ductility and Formability:

Hot rolled steel plates are highly ductile and can be easily formed and shaped into various configurations. This property is advantageous in industries such as automotive manufacturing and shipbuilding, where complex and custom shapes are required.

4. Weldability:

Hot rolled steel plates are well-suited for welding applications. They can be joined using various welding techniques, including arc welding, MIG welding, and TIG welding. This weldability is essential in industries that rely on the fabrication of steel structures and components.

5. Machinability:

Hot rolled steel plates have good machinability, allowing for efficient cutting, drilling, and machining processes. This feature is valuable in industries that require precision and accuracy in the production of steel components, such as the aerospace and machinery manufacturing sectors.

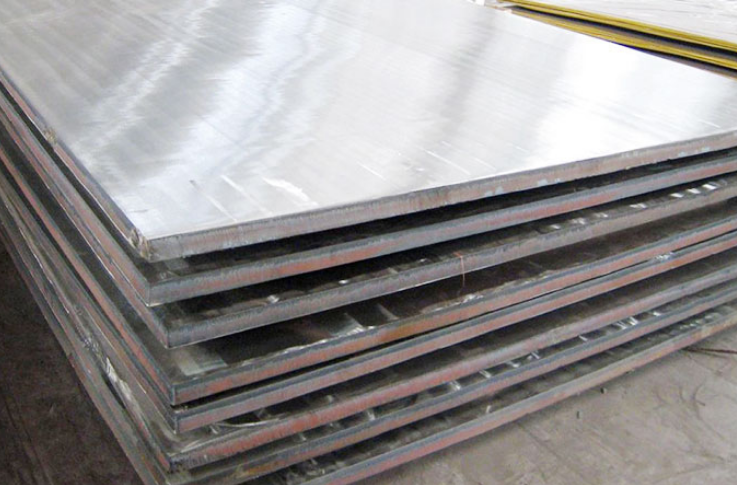

Stainless Steel Clad Plate (Hot Rolled)

6. Durability and Longevity:

Hot rolled steel plates are highly durable and resistant to wear and tear. This longevity is crucial in applications where the steel plates are exposed to harsh environmental conditions, such as in the construction of heavy machinery and agricultural equipment.

7. Wide Range of Sizes and Thicknesses:

Hot rolled steel plates are available in a wide range of sizes and thicknesses, offering versatility and flexibility in design and construction. This variety ensures that the plates can be tailored to meet the specific requirements of different projects and industries.

8. Versatility:

Hot rolled steel plates find applications in a broad spectrum of industries, including construction, automotive, manufacturing, energy, and more. Their versatility makes them a suitable choice for a wide array of projects and needs.

9. Rapid Production:

The hot rolling process is relatively quick, allowing for the rapid production of steel plates. This speed is advantageous in industries with tight deadlines and high demand, such as construction and infrastructure development.

Additional resources:Why is the price of tungsten rising?

Standards for Steel Pipes, Tubes and Fittings

AH Slurry Pumps: The Superior Choice for Efficient Mining Operations

10. Reduced Residual Stress:

Hot rolled steel plates typically have lower levels of residual stress compared to cold rolled plates. This reduced stress minimizes the risk of material distortion and cracking during processing, contributing to the overall quality and reliability of the plates.

Applications of Hot Rolled Steel Plates

Hot rolled steel plates are utilized in a diverse range of applications across various industries:

- Construction: Hot rolled steel plates are a primary choice for constructing buildings, bridges, and infrastructure due to their exceptional strength and durability.

- Automotive: These plates are used in the manufacturing of automobile frames, chassis components, and structural parts, benefiting from their high tensile strength and formability.

- Manufacturing: Hot rolled steel plates find use in the production of machinery, equipment, and various industrial components due to their machinability and versatility.

- Energy: The energy sector relies on hot rolled steel plates for applications such as the construction of pipelines, storage tanks, and pressure vessels, where durability and resistance to high temperatures and pressures are crucial.

- Aerospace: Hot rolled steel plates are employed in the aerospace industry to fabricate components that require precision machining and reliability.

- Shipbuilding: The shipbuilding industry relies on hot rolled steel plates for the construction of ship hulls and structures, benefitting from their weldability and formability.

- Agriculture: Hot rolled steel plates are used in the manufacturing of agricultural machinery and equipment, such as plows and harrows, due to their wear resistance and durability.

Conclusion

Hot rolled steel plates offer a myriad of advantages that make them a vital material in numerous industries. Their cost-efficiency, high tensile strength, ductility, weldability, and wide range of sizes and thicknesses make them suitable for a diverse range of applications. Whether in the construction of buildings, manufacturing of automotive components, or fabrication of industrial machinery, hot rolled steel plates continue to play a pivotal role in shaping our modern world. Their durability, versatility, and rapid production make them an essential choice for various projects and industries.